An hour away from DRMP’s Orlando, Fla., headquarters, Morton Salt produces more than 200,000 tons of swimming pool, premium water softener, and agricultural salts at its manufacturing plant in Cape Canaveral.

Up in Maumee, Ohio, our Trilon partner firm, Mannik & Smith Group (MSG), is developing a new floor plan for the Morton Salt plant in Florida with the assistance of DRMP as a subconsultant on the project.

Mobilizing resources on this project would have been difficult for MSG without collaboration from DRMP since the Ohio-based firm does not have offices in Florida. Our firm’s proximity to the Morton Salt plant combined with our LiDAR capabilities made this collaboration key to better serving the client.

This project also provided DRMP with a unique opportunity to perform work outside of our transportation market sector expertise.

DRMP’s LiDAR Capabilities

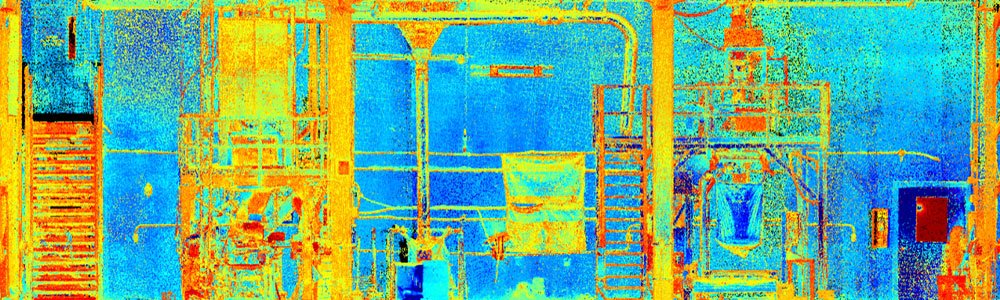

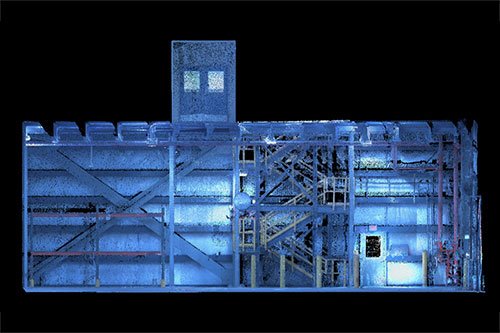

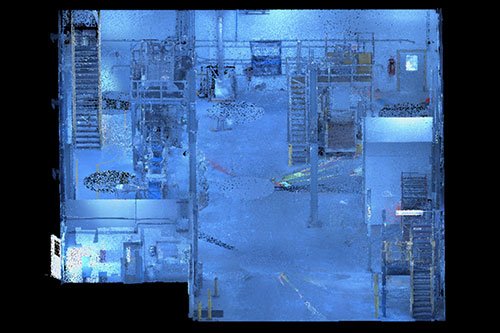

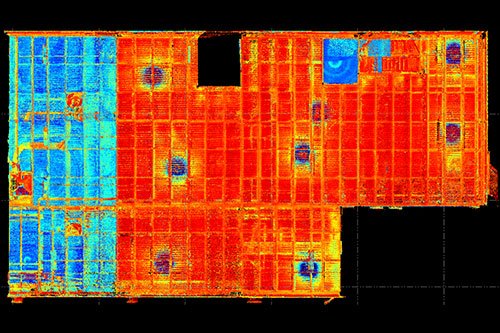

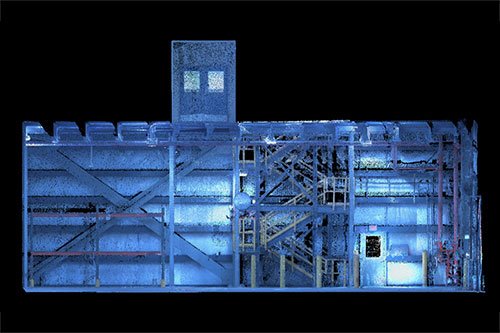

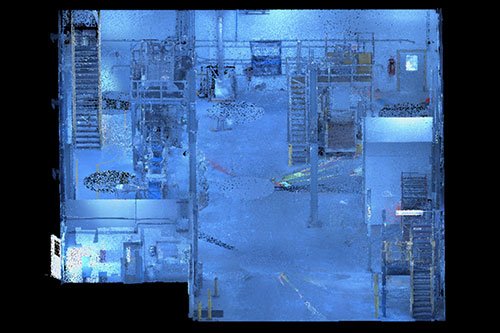

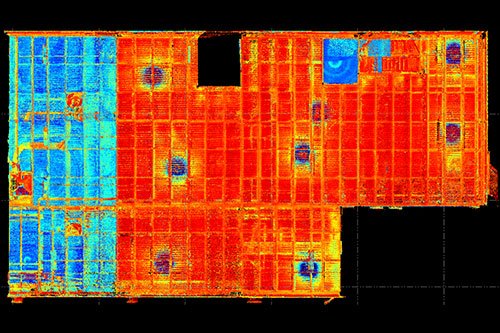

Our role in this project involved providing a static terrestrial LiDAR (light detection and ranging) scan of the existing layout of Morton Salt’s equipment to assist MSG with designing the new floor plan.

We used a Trimble X7 Terrestrial LiDAR sensor, a high-speed laser scanning system, to create a point cloud of the inside of the plant and provided it to MSG within two days.

The LiDAR sensor emits rapid and short laser pulses to scan and map out an environment. When the emitted laser pulses hit objects in the environment, they get reflected toward the sensor. The terrestrial LiDAR sensor records the time it takes for the laser pulse to travel from the sensor to the object and back. This is known as the time of flight and is measured with high precision using accurate timing devices and in turn creates a point. Each point in a point cloud represents a single spatial measurement, but there are millions of points. By the time the scan is complete, it looks photo realistic because there are so many points.

Without LiDAR capabilities, conventional methods of measurement would be used in this case locating all the items manually with a Total Station. This method would have taken more time, and in turn, would have shut down the salt production facility for much longer, affecting the client’s operations.

A Rare Opportunity

This has been a unique, collaborative opportunity for us since DRMP specializes in Survey services for transportation projects. We typically use LiDAR for scanning bridges and other vertical features, but our deliverable is quite different on those types of projects compared to the Morton Salt project. For this project, we are delivering a point cloud to MSG without having to extract the data.

When working on transportation projects, we would collect the point cloud data, review it, and extract the information using computer-aided design software, such as MicroStation CAD or AutoCAD, or by generating a PDF plan set.

Our collaboration with MSG not only allowed for decreased mobilization time but also enabled our partner firm to seek work outside of its geographical location. This project is a great example of advantageous and efficient use of teamwork while delivering quality service to the client.

Matt Floyd, PSM, serves as the Boca Raton Survey Department Manager for DRMP’s Survey and Mapping/Geospatial Market Sector. .