When I first joined DRMP in 2019, I stepped into a unique role. I was the firm’s first in-house electrical engineer. Before then, DRMP typically subcontracted all electrical design, which often meant delays when quick answers were needed. If a civil engineer wanted a fast estimate or needed to know whether an electrical concept was even feasible for a project, it wasn’t always easy to get that information promptly.

Now, our in-house electrical engineering team is filling that gap. We help streamline project coordination, reduce delays, and keep everything under one roof, which leads to a smoother experience overall.

As civil engineering has evolved to cover a broader spectrum of work with technological advancements, electrical engineers are now playing a far bigger role than most people might realize.

Having electrical engineers on staff, especially someone with Senior Electrical Engineer Steve Conway’s level of experience, has allowed us to take on new types of projects that were previously outside our wheelhouse. We’re now pursuing work related to wastewater and stormwater systems and branching into facility-based electrical work. It’s expanded the services we can offer and made us more versatile as a firm.

For example, DRMP is applying its electrical engineering expertise to help the City of Durham, N.C., expand its electric bus charging infrastructure, resolving transformer overloads and designing a high-capacity system fit for the future. Our firm is also conducting in-depth electrical assessments of stormwater lift stations in Hillsborough County, Fla., to help improve flood resilience following a historic hurricane event. And DRMP is leading the electrical design for a lift station upgrade in Melbourne, Fla., drawing on decades of experience to modernize critical infrastructure.

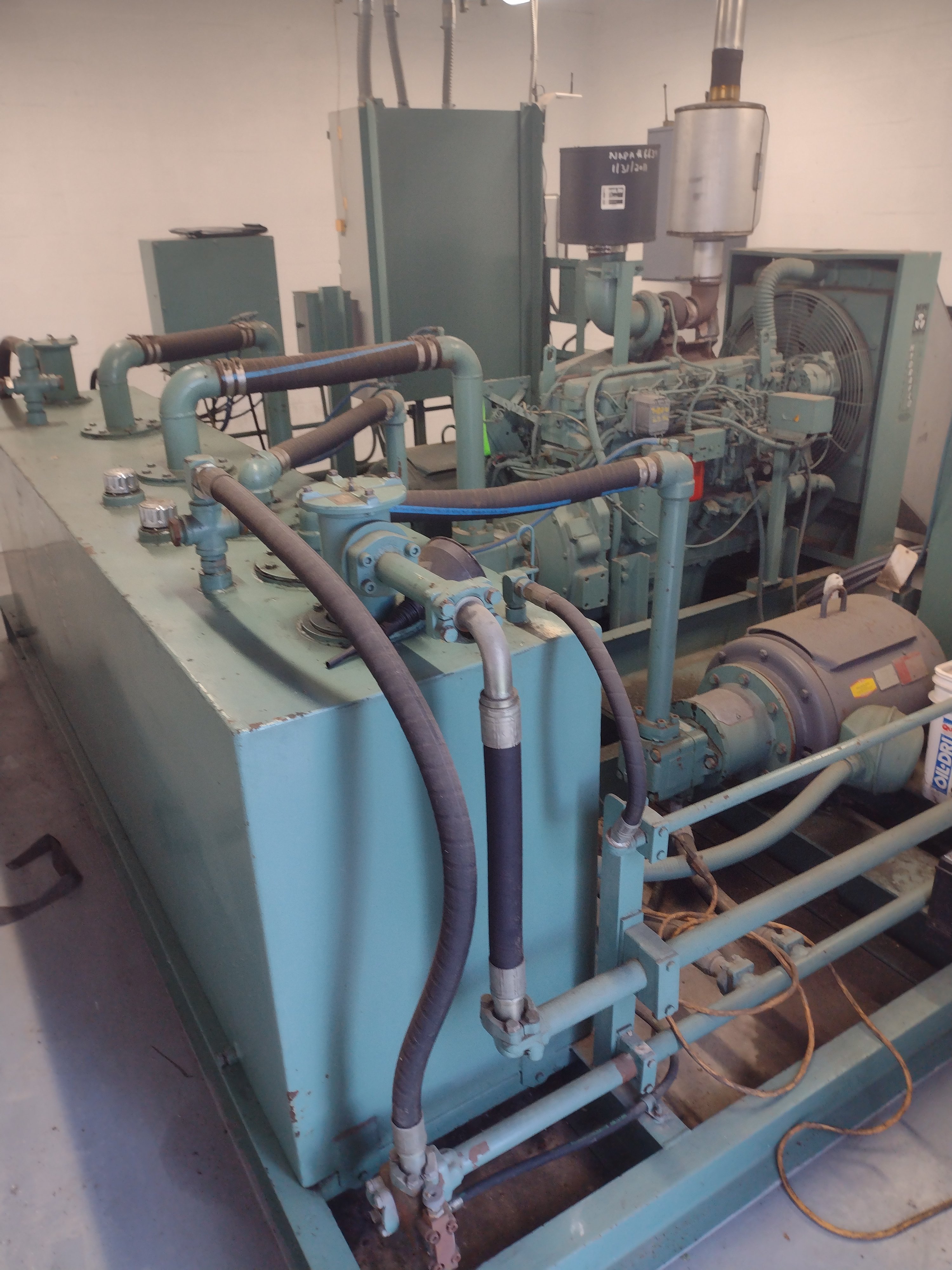

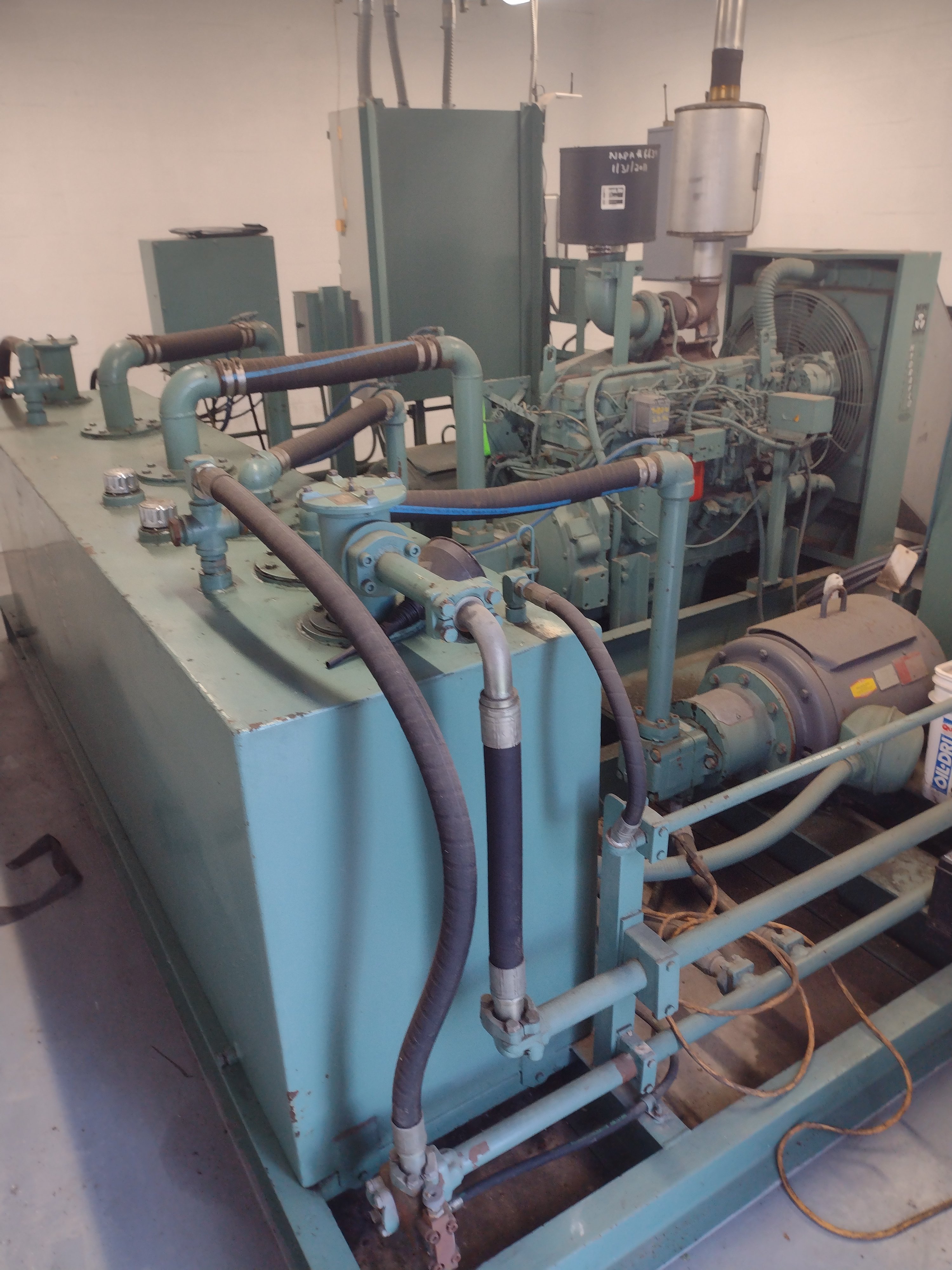

Justin Hayes, EI, gathers conductor and breaker sizes for electrical system analysis, while inspecting equipment condition for potential replacements due to age or malfunction.

Team Growth

Over the past year, DRMP has made a significant investment in expanding our electrical engineering capabilities. We've grown rapidly, adding five new electrical engineers to our team. Among them is Steve Conway, PE, who brings over 40 years of industry experience. Traffic Automation Engineer Nigel Atkinson, EI, brings six years of experience as an electrical engineer and I bring eight years as an electrician and 12 years as an electrical engineer. I’m also a licensed master electrician.

We’re also proud to have Gabriel Goldie, EI, a recent graduate who has already passed the Professional Engineer exam and is currently fulfilling the required experience to obtain his license. Traffic Engineers Esther Dar and Chandrika Somepalli, along with Engineer Technician Shedric Bryant, are recent graduates actively working toward their Engineer Intern (EI) certifications. This summer, we’re also fortunate to have Brooks Gerig joining us as an intern. Altogether, our team now includes eight electrical engineers – and growing.

Nigel Atkinson, EI, conducting a field visit to review delivered equipment in response to a Request For Information (RFI) regarding conduit installation. Our on-site assessment allowed DRMP to provide accurate guidance to the contractor.

Our electrical engineers have traditionally focused on transportation projects, such as traffic signals, roadway lighting, tolling systems, and Intelligent Transportation Systems (ITS). These systems include dynamic message signs, CCTV cameras, radar detectors, and even connected and autonomous vehicle technologies like roadside units. We've also worked on drawbridge electrical systems.

But our role extends beyond just transportation. We’ve been involved in a wide range of civil projects from an electrical standpoint, including parking lot lighting, electrical service design for buildings, stormwater and wastewater lift stations, and Electrical Vehicle (EV) charging facilities, to name a few.

As for EV charging, especially fleet conversions, it’s a rapidly expanding market. Many clients are still trying to understand what’s involved, and that uncertainty creates opportunity for firms like ours that are already gaining experience.

Our team is experienced working with both low-voltage and medium-voltage systems, tailored to project needs. For most transportation-related systems, such as tolling, traffic signals, roadway lighting, and ITS, we typically use low-voltage setups, generally 120/240V or 240/480V single-phase.

For larger infrastructure projects, particularly EV charging stations, transit depot electrification, or utility interconnections, we often work with medium-voltage systems, such as 12,470V. These are essential when managing large loads and mitigating voltage drop over long distances.

Florida's Turnpike Service Plaza featuring the FP&L EVolution electric vehicle charging station.

While low-voltage systems remain common for tolling and traffic systems and some EV charging installations, our recent EV charging projects have increasingly required medium-voltage solutions, especially at the utility interface or for large-scale facilities. Our team is proficient in both voltage ranges and adapts to meet the technical demands of each project.

Electrical Engineering Benefits

My background as a master electrician has been an asset, especially during the construction phase of projects when reviewing shop drawings. These drawings detail the materials contractors plan to use, like conductors, breakers, and load centers.

This part of the job is actually one of my favorites. Most engineers I know don’t love reviewing shop drawings, but I do because I’ve handled and installed most of these components in the field myself. That hands-on experience allows me to catch issues early, which helps avoid costly mistakes and delays. It’s essentially the final checkpoint before construction starts, and I take a lot of pride in getting it right.

Electrical and diesel backup motors powering the stormwater lift station at the Hillsborough County, Fla., project, ensuring reliable operation during severe weather.

That field perspective also helps when it comes to integrating electrical systems into infrastructure not originally designed for them. One of the biggest challenges is embedding conduits into concrete structures like bridges or foundations. That can get tricky. Fortunately, we have a range of installation methods, such as open trenching, directional boring, surface mounting, and overhead lines. Each has trade-offs in terms of disruption, cost, and aesthetics, but that flexibility helps us adapt to the existing conditions. Cutting into concrete is always a last resort, but it’s an option when needed.

Timing is another critical factor. Electrical work is usually a small piece of a larger project, so coordination is essential. Designs typically aren’t required until the 90 percent submittal stage, but we often need to see the 60 percent plans well in advance to begin our part. If a 90 percent deadline is sprung on us without much notice, we can be caught off guard. That’s why close communication with the project manager and early access to intermediate plans are key.

Over time, I’ve also seen how responsiveness builds stronger client relationships. My boss jokes that I say “yes” to everything, but I’ve found that when you consistently show up and solve problems, clients take notice. That kind of trust and mutual respect leads to better outcomes all around.

Future Growth Outlook

In the future, I think demand will grow in two main areas: lift station work and EV charging infrastructure. The lift station projects may not be massive individually, but there’s enough volume to make an impact.

At the end of the day, even when a project seems unfamiliar or intimidating, I’ve learned that the fundamentals remain the same. Whether it’s a CCTV camera, EV charger, or lift station, it always comes down to the basics: analyze the load, size the conductors, apply the proper protection, and follow the code. The systems may wear different “hats,” but the rules don’t change, and that consistency is what makes this work so rewarding.

Current Projects Requiring DRMP’s Electrical Engineering Expertise

City of Durham, N.C. – EV Bus Charging Facility Expansion

DRMP is working with the City of Durham on the expansion of their electric bus charging infrastructure. The city began with 10 200 kW chargers and buses as part of a successful pilot program. Now, they're expanding the system to include 20 additional chargers and buses.

Our team is tasked with identifying and resolving issues in the existing electrical system, which is currently experiencing transformer overloads. In parallel, we’re designing a new system that can handle the significantly increased electrical load and support the additional infrastructure.

Designing EV charging systems for public transit is a unique challenge. Each electric bus is equipped with an 800 kWh battery, comparable to the entire monthly energy consumption of a typical household. These charging systems demand power levels closer to those of a small substation than a traditional commercial service, requiring specialized electrical expertise to ensure reliability, safety, and scalability.

Hillsborough County, Fla. – Stormwater Lift Station Electrical Analysis

Following severe flooding during Hurricane Milton – a rare 500-year storm event – Hillsborough County initiated a comprehensive review of its stormwater lift stations. Many of these stations failed due to electrical vulnerabilities, including submerged control panels and a lack of backup power systems.

DRMP is evaluating 37 lift stations, providing detailed electrical assessments that include load calculations, conductor and breaker sizing, and strategic recommendations for relocating equipment above future flood levels. We're also analyzing the feasibility of integrating diesel-powered backup generators to ensure these stations remain operational during power outages. Our work will help strengthen the county’s stormwater infrastructure, improving resilience and reducing flood risk in affected communities.

City of Melbourne, Fla. – Lift Station Electrical Upgrade

The City of Melbourne is replacing aging equipment at one of its lift stations, and DRMP is handling the electrical design component of the project, but our team in Jacksonville, Fla., will be providing the electrical design for the new equipment. We are responsible for conducting load analysis, properly sizing conductors, and selecting appropriate overcurrent protection devices for the new pump system.

This project draws on DRMP Senior Electrical Engineer Steve Conway’s experience. He has designed more than 1,000 lift station electrical systems over his 40-plus year career, bringing a deep level of practical insight to this work.

Justin E. Hayes, EI, serves as the Jacksonville Traffic Group Leader and a Project Manager for DRMP’s Transportation Market Sector.